Angepasst

Bewerbungen

Außergewöhnliche Produktionen

Originelle Lösungen

Das Team von CAMdivision entwickelt eigens entwickelte Anwendungen aus der Serie “RAPID”, die die Arbeit in der NX CAD/CAM- und TEAMCENTER-Umgebung automatisieren und beschleunigen. Sie können die Form von eigenständigen Anwendungen oder Makros haben oder eng in eine bestimmte NX CAx-Umgebung integriert sein.

Ein Beispiel für eine solche Anwendung ist NX Rapid PROBING, das den Prozess der Teilemessung in der NX CAM-Umgebung automatisiert.

Basierend auf den spezifischen Anforderungen und Bedürfnissen des Kunden wird eine individuelle Konfiguration oder Anwendung erstellt, die den Produktionsprozess des Unternehmens auf die nächste Stufe hebt!

Spezielle Anwendungen

Rapid SERIES

NX Rapid PROBING ist das von CAMdivision angepasste Modul NX Probing. Je nach Maschinentyp und Verfügbarkeit von Messzyklen können Messungen u.a. an den Steuerungen Heidenhain, Fanuc, Sinumerik, OSP Okuma mit Blum oder Renishaw programmiert werden. Eine vollständige Prozesssimulation auf Basis des NC-Codes ist möglich, auch auf 5-Achs-Fräsmaschinen oder Dreh- und Fräszentren.

Beispieloperationen für NX Rapid Probing - HEIDENHAIN

Es ist möglich, mehrere Messzyklen und Kalibriervorgänge für gegebene geometrische Merkmale im NC-Code zu erzeugen.

- GEOMETRISCHE MERKMALE: 1) Messung der X-, Y- und Z-Koordinaten TCH PROBE 427 KOORDINATENMESSUNG TCH PROBE 419 BEZUGSPUNKT. OS, 2) Messung der externen Brücke TCH PROBE 426 MESSUNG DER EXTERNEN BRÜCKE TCH PROBE 409 BEZUGSPUNKT. INTERNE BREITENMESSUNG, 3) Innere Breitenmessung TCH PROBE 425 INTERNE BREITENMESSUNG TCH PROBE 408 BEZUGSPUNKT. MITTEL DER VERTIEFUNG 4) Winkelmessung Messungt TCH PROBE 420 WINKELMESSUNG TCH PROBE 400 GRUNDDREHUNG TCH PROBE 403 ROT DURCH C-Achse, 6) 3D-Messungt CH PROBE 4,0 MESSUNG 3D...

- KALIBRIERUNGSVORGÄNGE: 1) Kalibrierung des Sondenradius auf dem TCH PROBE 2.0 TS CALIBRATE Ring, 2) Kalibrierung Kalibrierung der TCH PROBE 9.0 TS CALIBRATE Sondenlänge. LÄNGE, 3) Kalibrierung R- und L-Sonde auf Kugel TCH PROBE 460 CALIBRATE TS...

Beispieloperationen NX Rapid Probing - SINUMERIK

Es stehen unter anderem folgende Messzyklen zur Verfügung:

- GEOMETRISCHE MERKMALE: 1) Kantenausrichtung - Punkt (CYCLE978) X-, Y-, Z-Koordinatenmessung, 2) Kantenabstand - Auslass (CYCLE997), 3) Kantenabstand - Vertiefung (CYCLE977), 4) Kantenabstand - Kantenausrichtung (CYCLE998) Winkelmessung in 2D-Ebene,, 5) 3D - Ausrichtung der Ebene (CYCLE998), 6) Bohrung - 1 Loch (CYCLE977)....

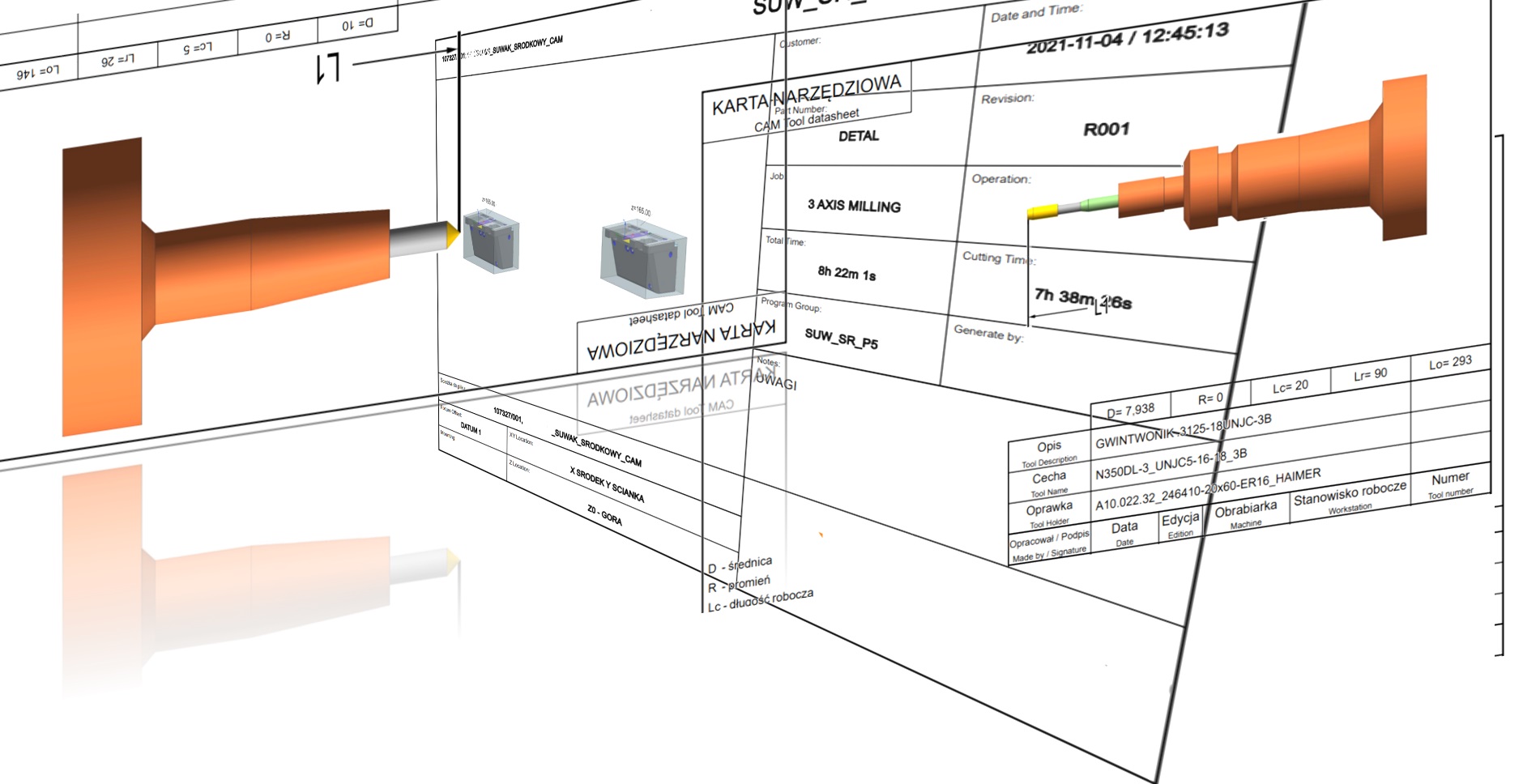

Extended machining reports include additional information in tabular form as a TXT or EXCEL file, HTML or PDF. Minimum/maximum tool overhang, additional operation numbering, renaming, wear and tear, data export to ERP or PLM system are some of the additional requirements we conduct in such projects. The ability to present this data on personalised 2D/3D drawings/documentation enables the elimination of paper documentation from the company's documentation workflow.

Data presentation

The possibility of presenting these data on personalised 2D/3D drawings/documentation enables controlling the workload of employees, tools, machines and transfer of these data to the DNC or PLM system. With such assumptions, it is possible to completely eliminate 2D paper documentation and move to the circulation of documentation compliant with Industry 4.0 standards.

The NX RAPID CAD module is an original CAMdivision package extending the NX CAD and NX DRAFTING applications with additional functionalities and fully integrated with them. The NX RAPID CAD module includes operations facilitating work with single parts, complete finished assemblies and flat documentation. The set of functionalities included in NX RAPID CAD was selected on the basis of the experience of our technical department as well as the suggestions of NX software users.

Exemplary features

The NX RAPID CAD license includes functions that facilitate activities related to modelling of single parts, individual operations, entire subassemblies and 2D documentation.

- Selected functions from the "Parts and operations" package: "Folder" function - opens and selects the exact location of the saved file in the "Windows Explorer" application – Operation "Rename" – Allows you to directly change the name of the working part as well as individual components in the assembly – Function "Copy part" – creates a non-associative copy of the working part or the selected component from the assembly, preserving the original

- Description of selected functions from the "Assemblies" package: The option "Copy part family to assembly folder" – copies all components that are created with the family ("standardized components") of parts to the main folder of the assembly. – ""Package assembly – packages all components of an assembly into one zip file.

- Description of selected functions from the "Mass" package: "Count mass" function – calculates the mass for the entire working assembly as well as all components and adds an attribute to them (the attribute name can be set individually by the user)

- Description of selected functions from the "Drafting" package: "Hide/Show view boundaries" operations – disables or enables the visibility of the boundaries of all views on the active sheet in the 2D drawing application.

NX Rapid MOLD is an additional package of configured NX Mold Wizard bases and tools supporting work in NX, which contains a number of start-up settings facilitating work according to standards in a given company. Thanks to its structure, it allows to maintain the consistency of data between all the constructors, as everyone uses the same configuration and works in a repeatable way. Thanks to this, another constructor can quickly take over work in order to continue it.

In addition to the start-up settings, it contains fully automated standardised parts. The current databases are based, among others, on a Polish manufacturer of standardised parts: PROPLASTICA (FCPK BYTÓW). NX Rapid MOLD contains a fully configured mould body, which includes standardised parts such as: plates, guide poles, guide pins, bushings, feet, rings, retractors, screws, bumper, etc. In addition, there is variability in the body, allowing additional screws, supports, insulation plates, locks, transport bar to be added very quickly.

Key features

Exemplary features NX Rapid MOLD reduces the time required to construct a mould by an average of 30%, and in some cases by as much as 50% compared to NX Mold Wizard alone.

Summary of features:

- PROPLASTICA (FCPK Bytow) databases of standardized parts and bodies.

- Slide and bevel databases with the ability to quickly add bolts and roll pins. The principle of generating bolts based on a point. By inserting a point, a bolt and a hole for it appear.

- Inserting ejectors with automatic positioning.

- Automatic engraving of the number on the ejector after definition of the item number in the list.

- Parametric body variants:

- inversion of plate guide columns;

- changing the position of the mould supply (moving the rings, the injection sleeve from the mould axis);

- changing the type of the buffer that drives the ejector plates (flanged, screwed, striped and screwed);

- quick change of number of screws and their point of attachment in the centring rings (screw recessed in the ring or protruding);

- addition of insulation boards with automatic positioning to a specific board;

- possibility to automatically add a second packet of ejector plates;

- possibility of making a gap between selected plates;

- possibility of editing the size of sleeve pillars without having to insert new solids;

- automation in adding bolt; adding a point generates a bolt and a hole in each plate;

- adding supports with automatic height selection and positioning;

- adding a transport bar with automatic positioning and length selection.

- ...

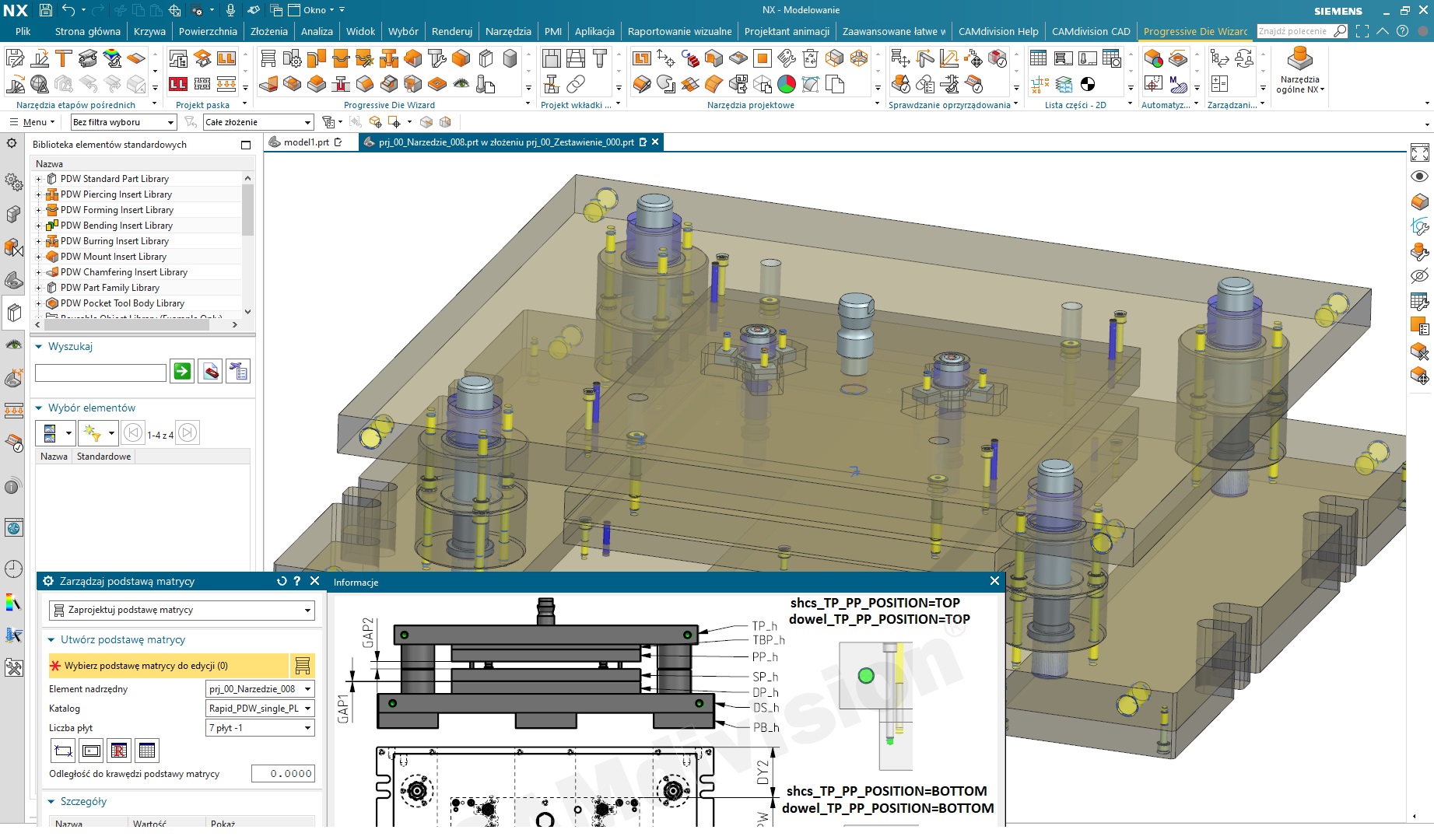

NX Rapid PROGRESSIVE is an add-in for the NX Progressive Die Wizard or NX Progressive Design applications. It contains a number of configured libraries compliant with the current practice used in the design of progressive and single-acting dies. Proper settings guarantee correct work and fast tool building.

Thanks to a large number of variants it is possible to build a tool with any number of plates. Currently the configuration is based on FIBRO, MXnorm and PROPLASTICA (formerly FCPK Bytow) catalogues.

Key features

Content of NX configurations for single and multi-taper dies:

- New structured assembly structure with division into upper and lower tool halves.

- Refined start-up settings: tolerances, colours, flat drawing, formers, etc.

- Multivariant body:

- Standard parts added to the tool:

- variable number of plates,

- smooth resizing without manual editing and without binding,

- variable number of screws (adding a screw based on a point, the added point will generate a screw and the corresponding hole and thread),

- variable number of guiding elements (columns, sleeves, etc.) automatic change of spacing of standard elements after a change in the tool dimension,

-

possibility to add plate modules to the tool.

- datums, poles, bushings, transport elements, punches, bending punches

- spacer plates, screw catalogues, dowels, jacks, springs, pivots.

- Automatic parts list based on inserted parts:

- automatic loading of catalogues, suppliers, materials, names, notes, etc.

- automatic determination of dimensions for parts added from the library,

- configured export to excel.

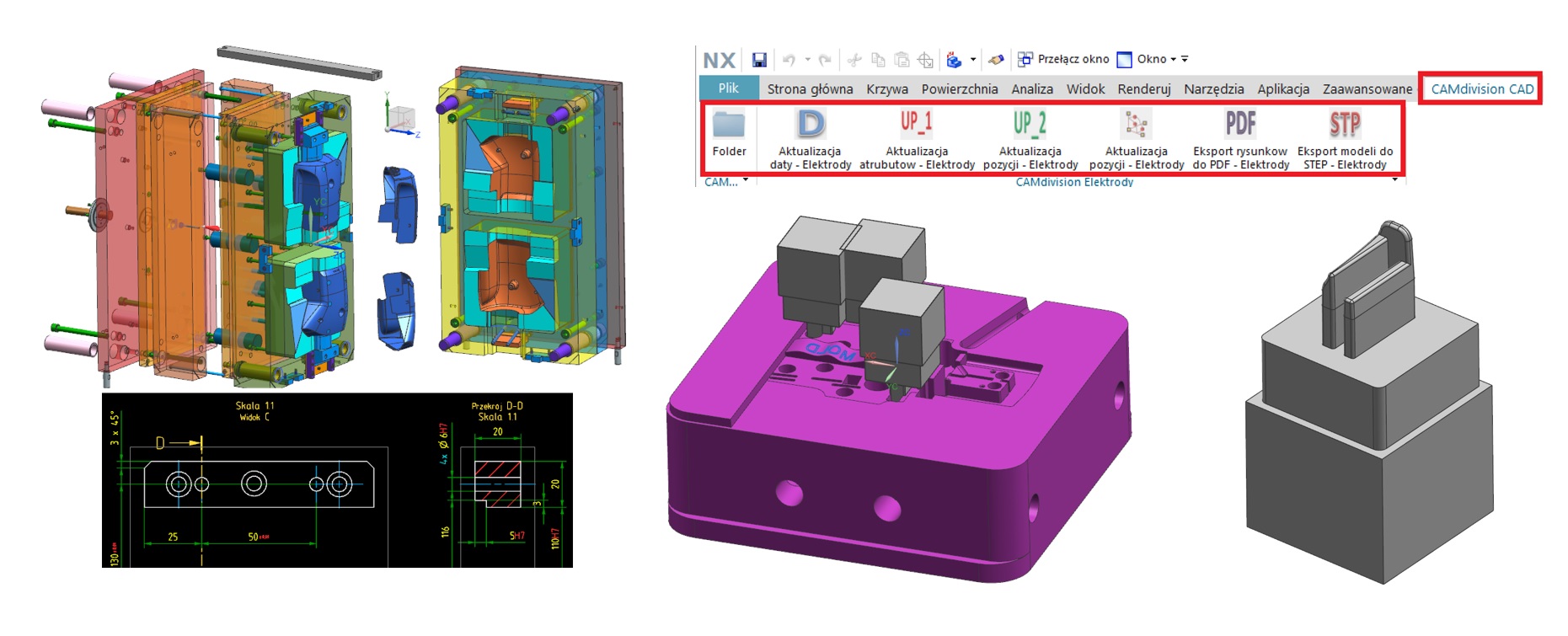

The application for creating electrodes is an add-in for NX containing databases of semi-finished products for electrodes and holders. It enables automatic generation of an assembly tree with electrodes, repeatable for all technologists. Automation in electrode workpiece creation (automatic generation of solids for closed ribs, automatic generation of a negative that needs to be processed by removing unnecessary walls). Includes commands to manage the list of electrodes with the possibility to edit the information that will be displayed on the runway card.

Rapid EDW is an add-on for the NX Electrode Design application. It contains personalized settings that maximally accelerate the creation of electrodes and documentation.

.

Selected features

- Automatic opening of the folder in which we are working - opening a file from the history, the program searches and opens the folder in which the file is located

- Automatic adding of date to all files or selected ones – the program adds the system date to the electrode

- Automatic updating of entries for manually moved electrodes – the program has the possibility of updating up to 20 positions of one electrode after manual moving

- Updating of electrode attributes – the program enables loading of file names to attributes thanks to which flat documentation is filled: electrode number, project name, part's own name

- Generating an overrun by angle – the program enables to select an electrode, then move it by a given angle and generate a starting point (start). The start and end coordinates appear on the flat documentation

- Automatic generation of lead-in cards from all electrodes to PDF files with names corresponding to the names of the electrodes

- Automatic generation of all electrodes to STP format as single files with the name of the electrode

Every solution is possible

You just need a proper expert team

The CAMdivision team is a group of specialists who will transform each order for additional configuration of the NX CAD/CAM environment into a fully efficient system with post-processors and virtual machines implemented at the highest level. We create original applications, the implementation of which is performed individually for a specific customer on the basis of precise guidelines and according to individual preferences resulting from the specificity of production.

Customized Software

NX CAD/CAM & Teamcenter offer the possibility of extending their functionality, which the CAMdivision team uses in every implementation. Post-processors, virtual machines, additional applications, macros and specialised CAD/CAM modules – all these require the skilled use of a particular programming language when preparing the implementation for the customer.