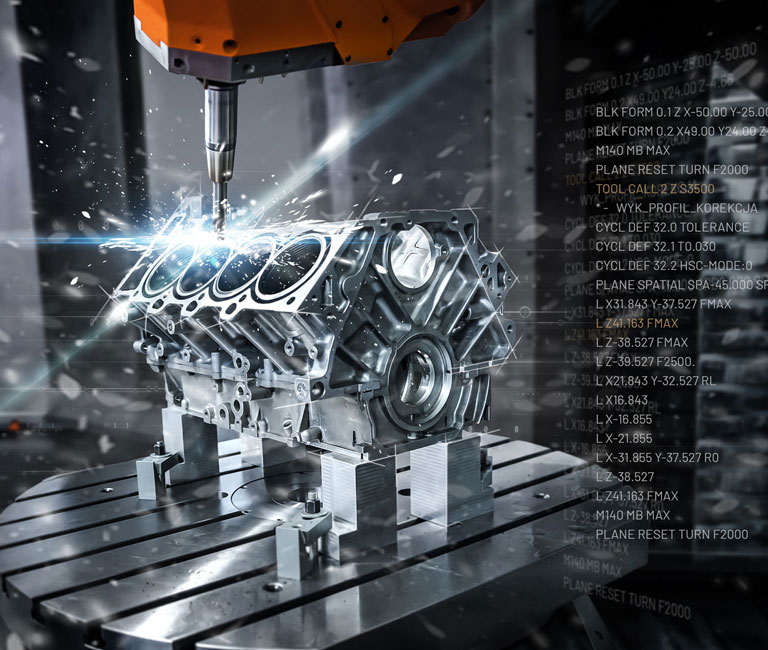

Pre Post-Processor

Pre Post-ProcessorNX CAM post-processors enable realistic simulation of part machining in the 3D kinematics space of the machine tool based on the NC code with taking into account the dynamics of the machine.

Detailed testing

Detailed testingBefore the implementation of the completed configuration of the post-processor and the virtual machine, a test piece is run on the machine during which particular types of movements and cycles are checked.

CODING WITHOUT LIMITS

Functionality without restrictions

Unique Vision

Our aim is to provide – backed by many years of experience – an optimal solution equipped with additional functions and applications that automate the work of the programmer and the machine.

Excellense & Engineering

We provide optimal solutions that use the full capabilities of the machine and control system. Our post-processors are implemented in Poland, Germany, Slovenia, Sweden, USA, Israel, Saudi Arabia...

Reliable expertise

We are constantly improving our qualifications by participating in training courses for machine, tool and software manufacturers, which allows us to provide high quality solutions.

Unmatched Experience

Our team members have over 20 years of experience in implementing post-processors for various types of machines, robots, printers with diverse kinematics and controls.

Complete documentation

Complete documentationTechnological documentation in the form of a list of tools or operations can be generated as simplified or extended, illustrating all process stages in detail.

Final protocol

Final protocolThe implementation and commissioning of the post-processor on the CNC machine is concluded with the signing of a technical acceptance protocol for the post-processor by both parties.

Fast upgrade

Fast upgradeThanks to the special structure of our applications and post-processors, upgrading to the next new NX CAM releases is fast and efficient. Check out new features!

World class support

World class supportA special Technical Support Panel – in Polish and English – allows efficient communication with the client and quick response to reported issues.